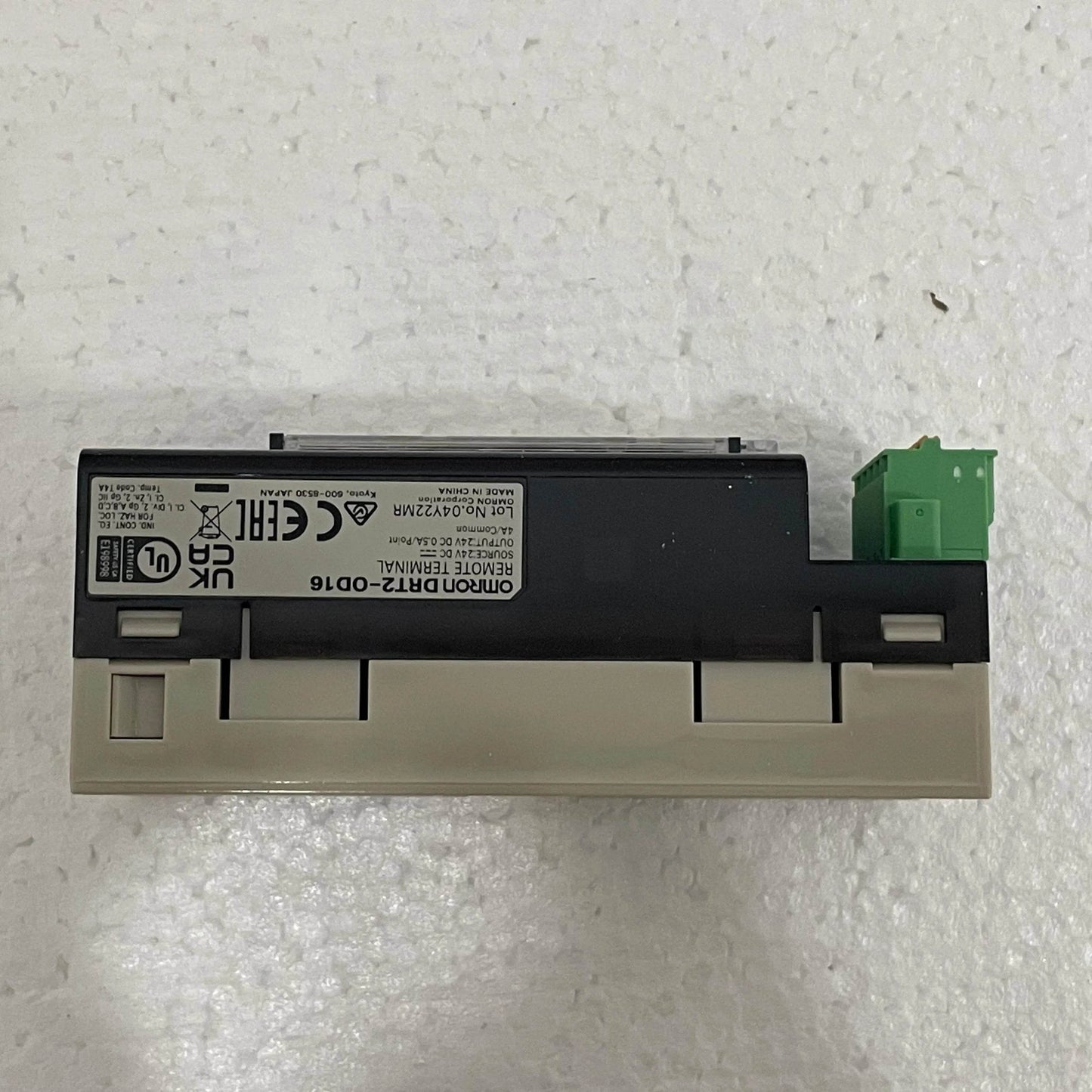

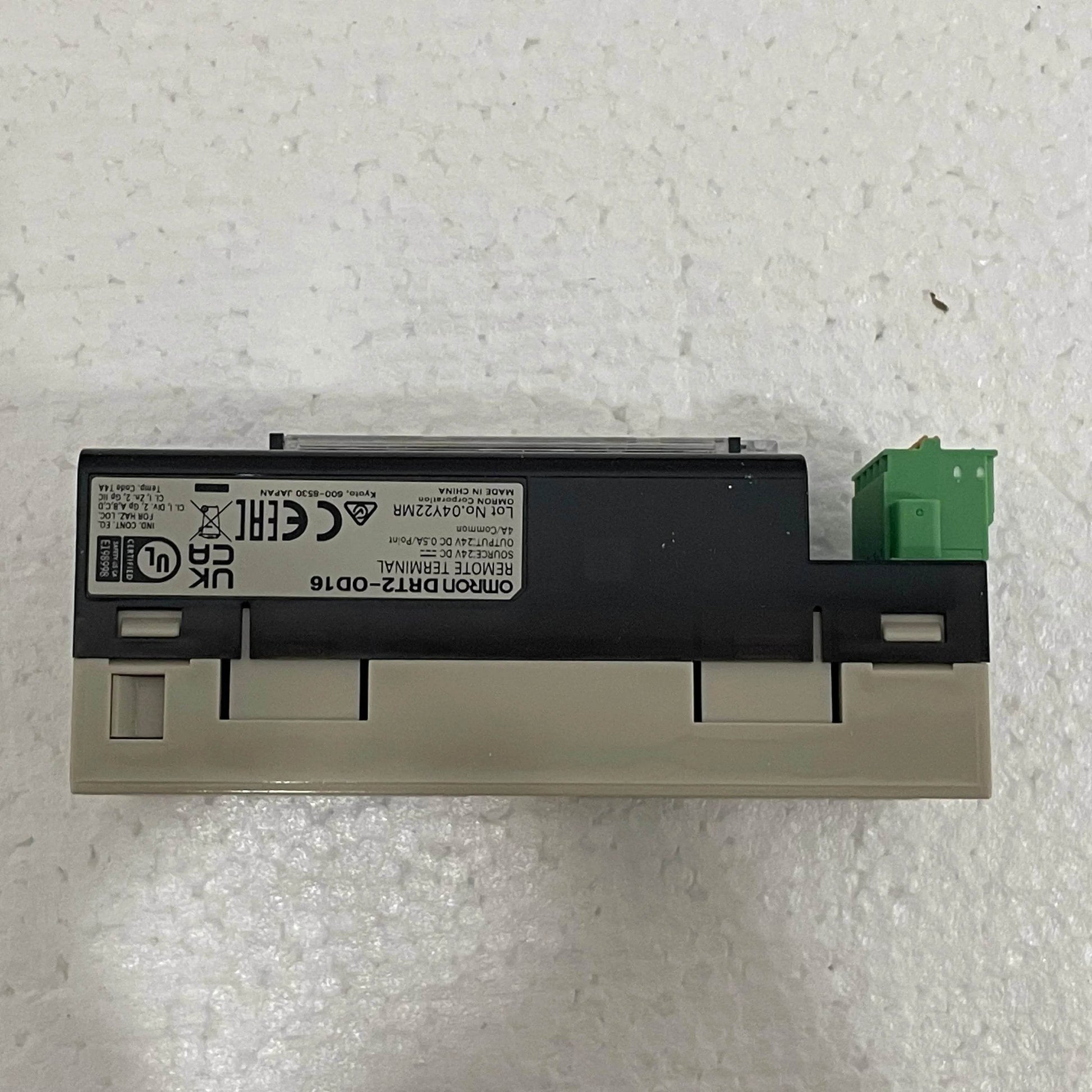

16-Channel Digital Output Module DRT2-OD16 for High-Speed PLC Systems

16-Channel Digital Output Module DRT2-OD16 for High-Speed PLC Systems

SKU(재고 관리 코드):DRT2-OD16

Package size: 17X10X10CMOmron DRT2-OD16 Digital Output Module | 16-Point Sourcing Transistor Unit for DeviceNet Networks

The Omron DRT2-OD16 represents the pinnacle of industrial automation technology, delivering 16 high-speed digital outputs in a rugged, space-efficient package. As a critical component of Omron's DeviceNet-compatible DRT2 Series, this industrial-grade output module provides exceptional reliability for controlling actuators, solenoids, and other DC loads in harsh manufacturing environments. Engineered for precision and durability, the DRT2-OD16 features advanced transistor output technology with comprehensive electrical protection, making it ideal for demanding applications across automotive, packaging, material handling, and process control industries.

Key Features and Technical Advantages

- High-Density Industrial Output Module: 16 independent sourcing (NPN) transistor outputs in an ultra-compact 31mm × 98mm × 65mm (W×H×D) form factor, enabling maximum I/O density in control panels and automation cabinets.

- Precision Voltage Regulation: Operates across a wide 10.2-26.4 VDC range (12-24 VDC nominal) with ±10% ripple tolerance, ensuring stable performance in fluctuating power conditions common in industrial settings.

- Robust Current Handling Capability: Each output channel supports 0.5A maximum continuous current (with 4A total unit capacity), capable of directly driving industrial solenoids, small motors (up to 100W), and pilot relays without additional amplification.

- Ultra-Fast Switching Performance: ≤1ms response time for both ON→OFF and OFF→ON transitions (including sensing and output delay), critical for high-speed automation sequences and precision timing applications.

- Advanced Electrical Protection: Integrated free-wheeling diodes protect against inductive load voltage spikes, while photocoupler isolation (1,500VAC for 1 minute) between internal logic and output circuits prevents noise-induced malfunctions.

- Energy-Efficient Design: Low 2.5W typical power consumption reduces heat generation and energy costs, with optimized heat dissipation through the aluminum housing.

- Industrial Environmental Ratings: Operates reliably in -25°C to +55°C temperatures with 25-85% non-condensing humidity, resistant to vibration (10-150Hz) and shock (147m/s²) per IEC 60068-2 standards.

- Simplified Installation: Tool-less DIN rail mounting (35mm) with positive locking mechanism, plus direct panel mounting options for flexible cabinet integration.

- Omron Quality Assurance: Backed by a 1-year manufacturer warranty covering defects in materials and workmanship, with manufacturing processes certified to ISO 9001 quality standards.

Industrial Applications and Use Cases

The DRT2-OD16 digital output module delivers reliable performance in these critical automation scenarios:

- Automated Assembly Systems: Precise control of pneumatic cylinders, indexing tables, and robotic tool changers in automotive and electronics manufacturing lines.

- High-Speed Packaging Lines: Synchronized activation of fillers, cappers, labelers, and case packers with millisecond-level timing accuracy.

- Warehouse Automation: Distributed control of conveyor diverters, stacker cranes, and automated guided vehicle (AGV) charging systems in logistics centers.

- Food and Beverage Processing: Hygienic design suitable for controlling pumps, valves, and heating elements in washdown environments (when properly enclosed).

- Plastic Injection Molding: Reliable operation in electrically noisy environments to control ejectors, core pulls, and peripheral equipment.

- Test and Measurement Systems: Precise triggering of measurement devices and data acquisition equipment in laboratory automation setups.

Comprehensive Technical Specifications

| Parameter | Detailed Specification |

|---|---|

| Manufacturer Part Number | DRT2-OD16 (Genuine Omron DeviceNet Slave Unit) |

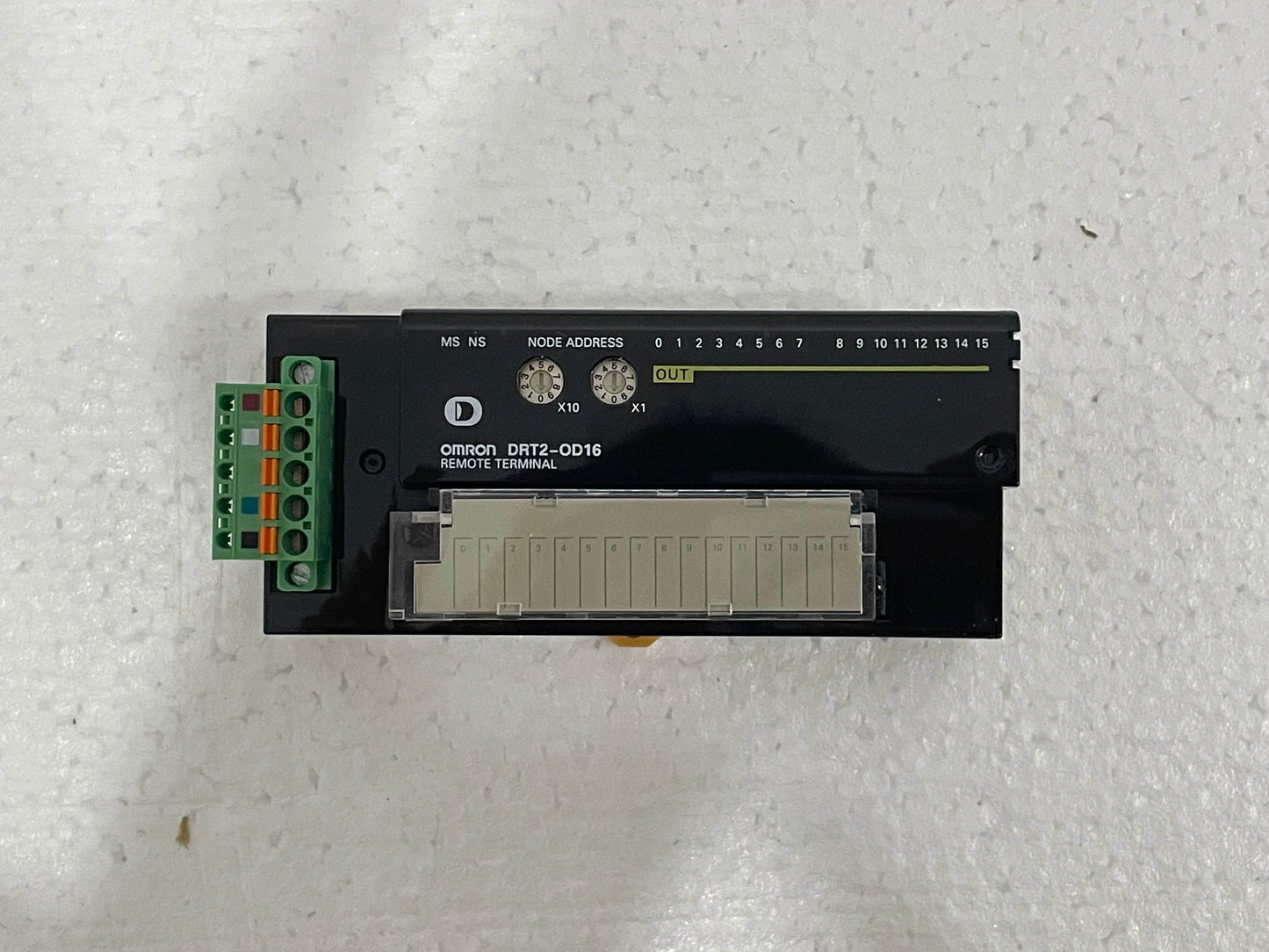

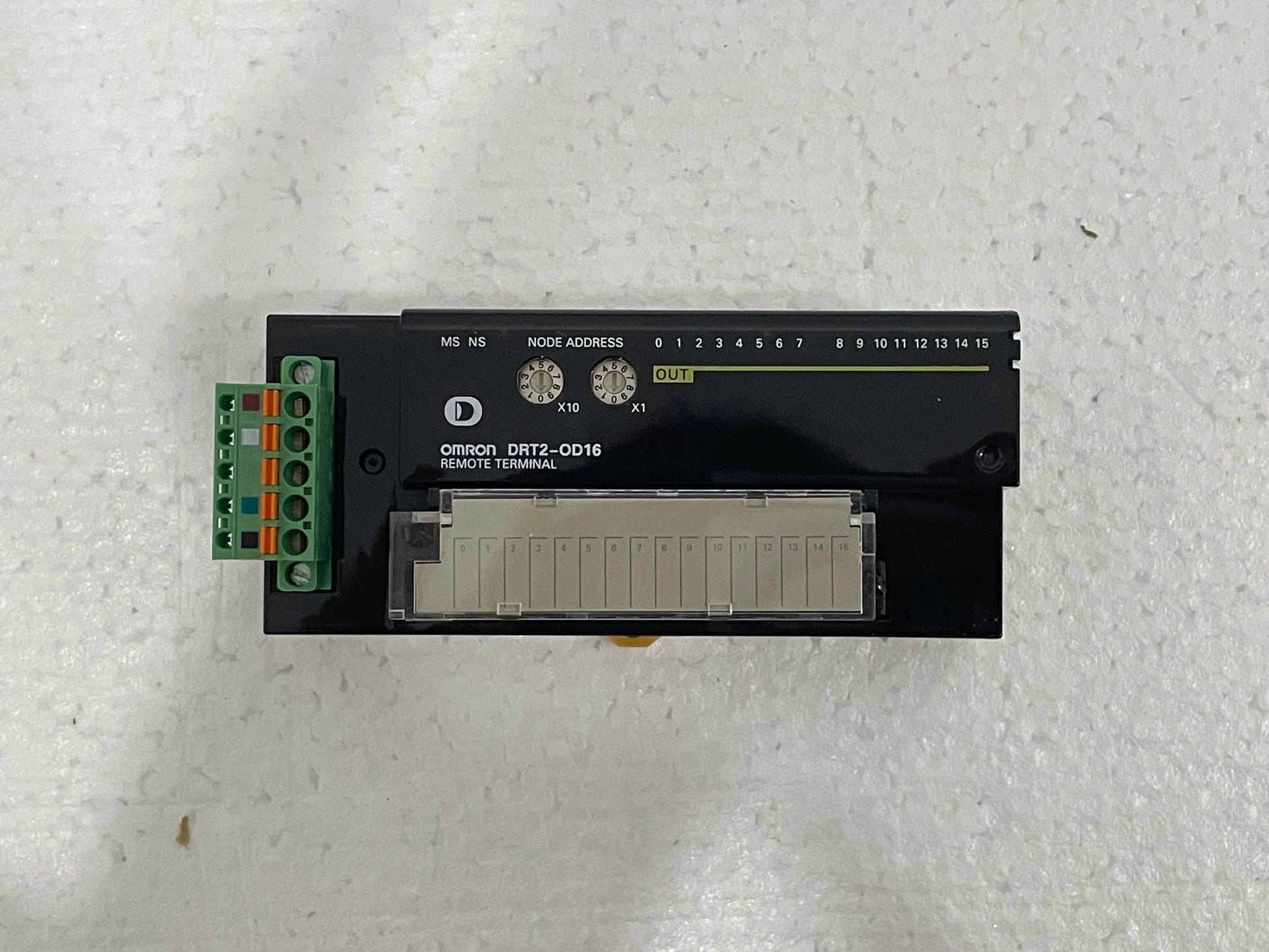

| Output Configuration | 16-point NPN transistor (sourcing) with individual status LEDs |

| Output Circuit Protection | Built-in free-wheeling diodes (for inductive loads) and overload protection |

| Load Voltage Range | 10.2-26.4 VDC (12-24 VDC nominal, ±10% ripple permitted) |

| Current Ratings | 0.5A per point (4A total unit current with derating above 0.3A/point) |

| Electrical Characteristics | OFF-state leakage current ≤0.1mA, ON-state voltage drop ≤1.5V |

| Switching Performance | 1ms maximum response time (ON/OFF), 100μs minimum pulse width |

| Isolation Ratings | Photocoupler isolation (1,500VAC for 1 minute) between internal circuits and outputs |

| Environmental Specifications | Operating: -25°C to +55°C, Storage: -40°C to +70°C, 25-85% RH non-condensing |

| Mechanical Specifications | 31mm × 98mm × 65mm (W×H×D), 150g ±5%, zinc-coated steel housing |

| Mounting Options | 35mm DIN rail (conforms to EN 60715) or direct panel mounting |

| Vibration/Shock Resistance | 10-57Hz: 0.075mm, 57-150Hz: 9.8m/s²; 147m/s² shock (3 times each axis) |

| Compliance Standards | CE, UL, CSA, RoHS compliant; meets EN 61131-2 for programmable controllers |

| Warranty Coverage | 1-year limited warranty from date of purchase (proof of purchase required) |

System Integration and Network Compatibility

The DRT2-OD16 seamlessly integrates with Omron's DeviceNet network architecture using standard 5-pin open-style connectors (requires separate DRT1-C08-1 or DRT2-C08-1 bus connector). The module supports both polled and bit-strobe communication modes, with configurable MAC ID via rotary switches. Bright dual-color LEDs provide comprehensive diagnostics including power status, network activity, and individual channel status. When combined with other DRT2 series modules (such as analog I/O units or temperature input modules), the system enables complete distributed control solutions with reduced wiring costs and improved maintainability.

Installation and Maintenance Considerations

For optimal performance, install the DRT2-OD16 in well-ventilated control panels away from high-voltage power lines (>200mm separation recommended). Use appropriate wire gauges (18-16 AWG recommended) and observe polarity when connecting loads. The module's screwless clamping terminals accept solid or stranded wires (0.3-2.5mm²), with torque specifications of 0.5-0.6 N·m. Regular maintenance should include visual inspection for dust accumulation and verification of terminal tightness during scheduled downtime. The product does not contain user-serviceable components and should not be disassembled.