Compact Slot-Type Photomicrosensor EE-SX951-W-G with 5mm Sensing Gap and IP50 Rating

Compact Slot-Type Photomicrosensor EE-SX951-W-G with 5mm Sensing Gap and IP50 Rating

Артикул:EE-SX951-W-G

Package size:Omron EE-SX951-W-G Photoelectric Sensor: Comprehensive Product Overview

The Omron EE-SX951-W-G represents the pinnacle of precision in through-beam photoelectric sensing technology, specifically engineered for industrial automation applications requiring uncompromising reliability. This advanced sensor system comprises two distinct components: an infrared emitter (EE-SX951) and a matching receiver (EE-SX951R), designed to work in perfect synchronization. The through-beam configuration ensures superior detection accuracy by measuring the interruption of an infrared light beam between the precisely aligned emitter and receiver units. With its robust construction and advanced optical technology, this sensor delivers consistent performance even in demanding industrial environments where vibration, ambient light interference, and space constraints present significant challenges.

Key Features and Technical Advantages

- Ultra-Precise Object Detection: The through-beam design with fixed 5mm sensing gap provides exceptional detection accuracy for objects as small as 0.1mm, making it ideal for high-precision manufacturing applications.

- Industry-Leading Response Time: With a blazing-fast 0.5ms response time (both ON and OFF), this sensor outperforms competitors in high-speed automation scenarios, capable of handling up to 2,000 detection operations per second.

- Wide Voltage Compatibility: The 5-24 VDC operating range (±10% tolerance) ensures seamless integration with virtually all industrial control systems, from legacy 5V circuits to modern 24V PLC architectures.

- Advanced Infrared Technology: The 850nm wavelength infrared LED light source provides superior immunity to ambient light interference while maintaining consistent performance across the sensor's -25°C to +55°C operating temperature range.

- Space-Optimized Design: The compact form factor (10.2 × 31 × 10.8 mm) with integrated mounting holes allows for installation in space-constrained locations without sacrificing detection performance.

- Flexible Output Configuration: User-selectable Light-ON/Dark-ON operation via internal DIP switches enables quick adaptation to diverse application requirements without additional components.

- Industrial-Grade Durability: The UL94 V-0 flame-resistant plastic housing with IP50 protection ensures reliable operation in typical manufacturing environments with moderate dust exposure.

- Omron Quality Assurance: Backed by Omron's industry-leading 1-year manufacturer warranty, providing confidence in product reliability and performance.

Detailed Technical Specifications

| Parameter | Detailed Specification |

|---|---|

| Complete Model Number | EE-SX951-W-G (Emitter) and EE-SX951R-W-G (Receiver) - sold as matched pair |

| Detection Method | Through-beam photoelectric (separate emitter and receiver units) |

| Power Requirements | 5-24 VDC (±10% ripple), reverse polarity protected |

| Current Draw | Emitter: ≤15 mA @ 12VDC; Receiver: ≤20 mA @ 12VDC (including load current) |

| Output Type | NPN open collector (sinking output), max. 100mA load current |

| Response Characteristics | 0.5ms max. response time (both ON and OFF transitions) |

| Optical Specifications | 850nm infrared LED, Class 1 LED product (IEC 60825-1 compliant) |

| Sensing Configuration | Fixed 5mm gap between emitter and receiver (precise alignment required) |

| Output Logic | Configurable via DIP switch (Light-ON/Dark-ON operation) |

| Environmental Protection | IP50 (protected against limited dust ingress, not waterproof) |

| Temperature Range | Operation: -25°C to +55°C (no condensation or icing); Storage: -30°C to +70°C |

| Construction Materials | Engineering-grade plastic housing (UL94 V-0), nickel-plated brass mounting hardware |

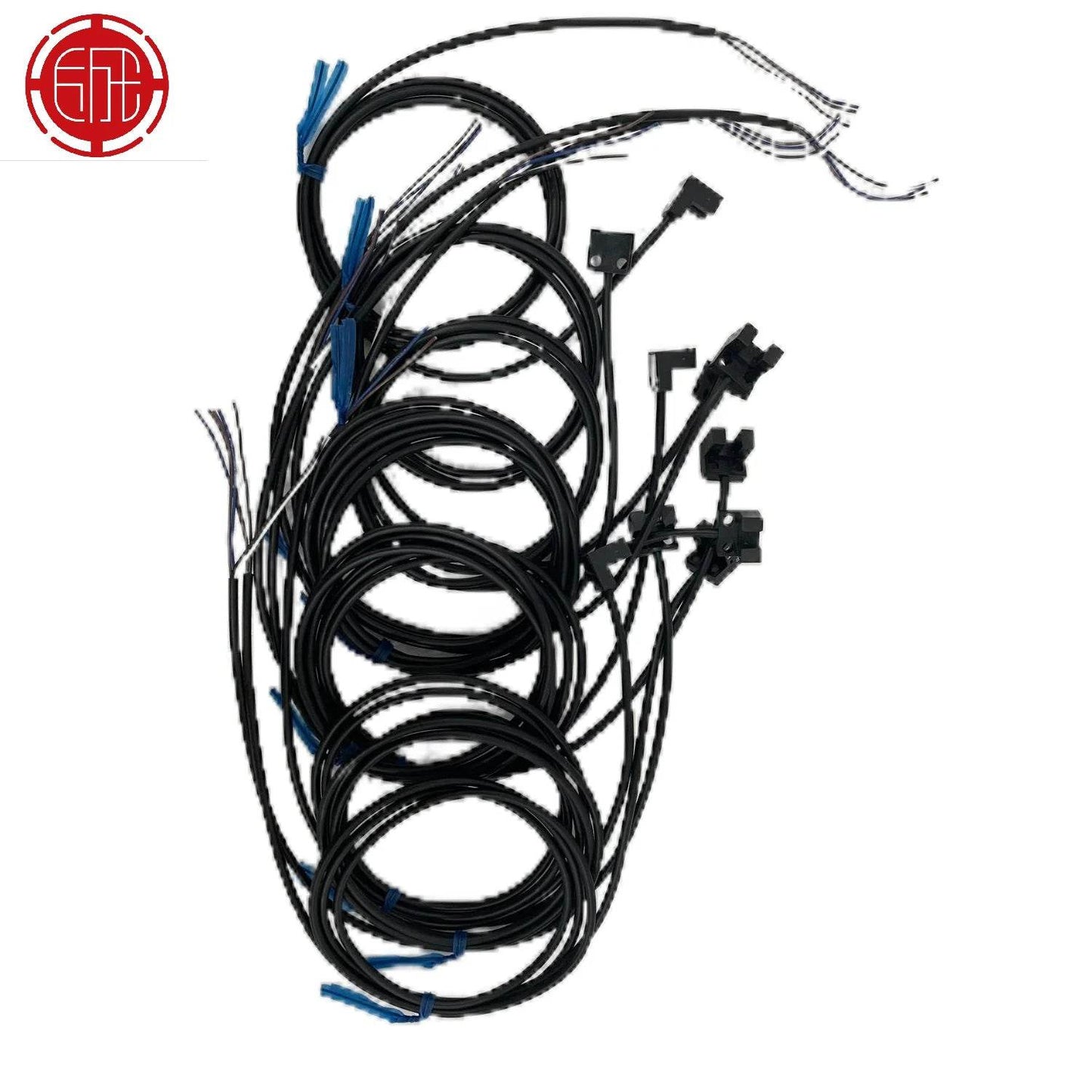

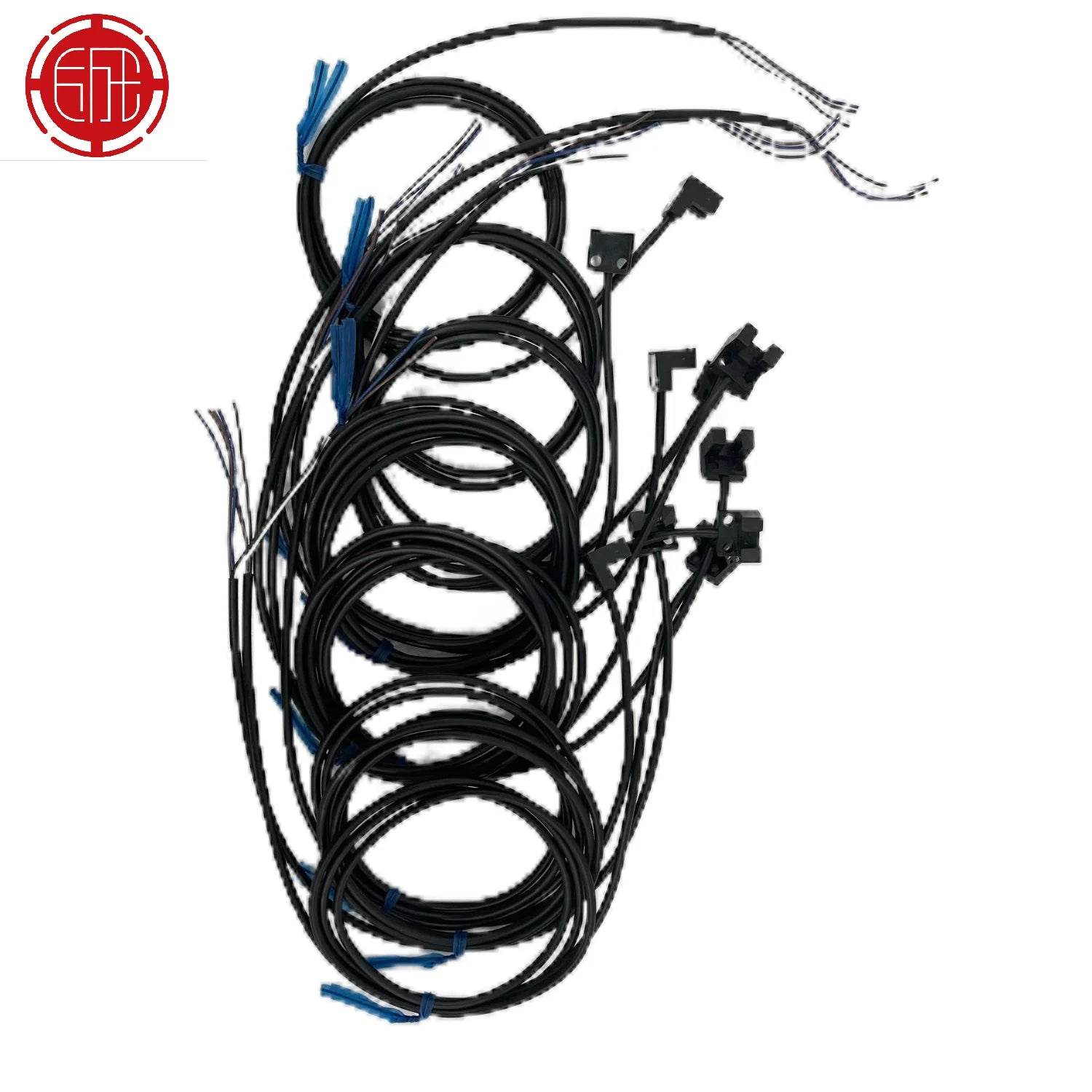

| Electrical Connection | Pre-wired 2m cables (standard length) with stripped ends for termination |

| Expected Service Life | Minimum 100,000 hours MTBF (Mean Time Between Failures) |

Industrial Applications and Use Cases

The Omron EE-SX951-W-G photoelectric sensor excels in numerous industrial automation scenarios:

- Precision Assembly Systems: Micro-component detection in watchmaking, medical device manufacturing, and electronics assembly where sub-millimeter detection accuracy is critical.

- High-Speed Packaging Lines: Product counting, orientation verification, and missing component detection in pharmaceutical and food packaging applications operating at speeds up to 1,200 packages per minute.

- Printing and Paper Handling: Reliable sheet feed detection in commercial printing presses, preventing costly multi-sheet feeds and paper jams.

- Robotic Workcell Integration: Precise end effector positioning verification and part presence confirmation in automated welding and material handling robots.

- Precision Assembly Systems: Micro-component detection in watchmaking, medical device manufacturing, and electronics assembly where sub-millimeter detection accuracy is critical.

- High-Speed Packaging Lines: Product counting, orientation verification, and missing component detection in pharmaceutical and food packaging applications operating at speeds up to 1,200 packages per minute.

- Printing and Paper Handling: Reliable sheet feed detection in commercial printing presses, preventing costly multi-sheet feeds and paper jams.

- Robotic Workcell Integration: Precise end effector positioning verification and part presence confirmation in automated welding and material handling robots.

- Conveyor Monitoring: Object detection and counting on high-speed conveyor systems in logistics and distribution centers.

- Machine Safety Applications: Non-contact position verification for interlock systems and light curtain monitoring in industrial safety setups.

- Semiconductor Manufacturing: Wafer handling and processing equipment where cleanroom-compatible sensors are required.

- Automotive Production: Small part verification in fuel injection systems, transmission assembly, and electronic component manufacturing.

- Maintain precise 5mm (±0.2mm) gap between emitter and receiver faces for optimal detection reliability

- Use provided mounting holes with M3 screws (recommended torque 0.5N·m) to ensure vibration-resistant installation

- Keep optical surfaces clean using only approved lens cleaning solutions and lint-free wipes

- Implement proper cable strain relief within 150mm of sensor connection points

- When installing in high-vibration environments, consider using vibration-damping mounts

- For best EMI immunity, route sensor cables separately from power lines and motor conductors

- Verify alignment periodically (recommended every 6 months in continuous operation)

- CE Marking (EMC Directive 2014/30/EU, Low Voltage Directive 2014/35/EU)

- RoHS 3 Compliance (EU 2015/863)

- UL Recognition (UL508 Industrial Control Equipment)

- IEC 60947-5-2 (Low-voltage switchgear and controlgear - Proximity switches)

- EN 60947-5-2 (European standard for proximity devices)

Industrial Applications and Use Cases

The Omron EE-SX951-W-G photoelectric sensor excels in numerous industrial automation scenarios:

Installation Guidelines and Best Practices

To maximize the performance and longevity of your EE-SX951-W-G photoelectric sensor system:

Regulatory Compliance and Quality Standards

The EE-SX951-W-G meets or exceeds the following international standards:

This Omron product is covered by a standard 1-year manufacturer's warranty against defects in materials and workmanship when used under normal operating conditions. The warranty period begins from the date of original purchase. Proof of purchase is required for warranty service. This warranty does not cover damage resulting from improper installation, misuse, or unauthorized modifications. Refer to the official Omron warranty documentation for complete terms and conditions.